Tailor-made coatings

The Stages of the Creation of one of our coatings

-

Phase 1: Measurements and Coating Application

The first phase consists in cleaning the tank to be coated, which is followed by precise measurements of the dimensions, carried out by one of our Expert Operators.

Using state-of-the-art techniques and tools, the coating will then be applied to the tank.

-

Phase 2: Leak test

Subsequently we will make sure of its total watertightness, not by resorting to conventional tightness tests, but by using the Scintillograph, which allows you to identify any leaks in a few minutes, without a great expenditure in terms of time and water.

-

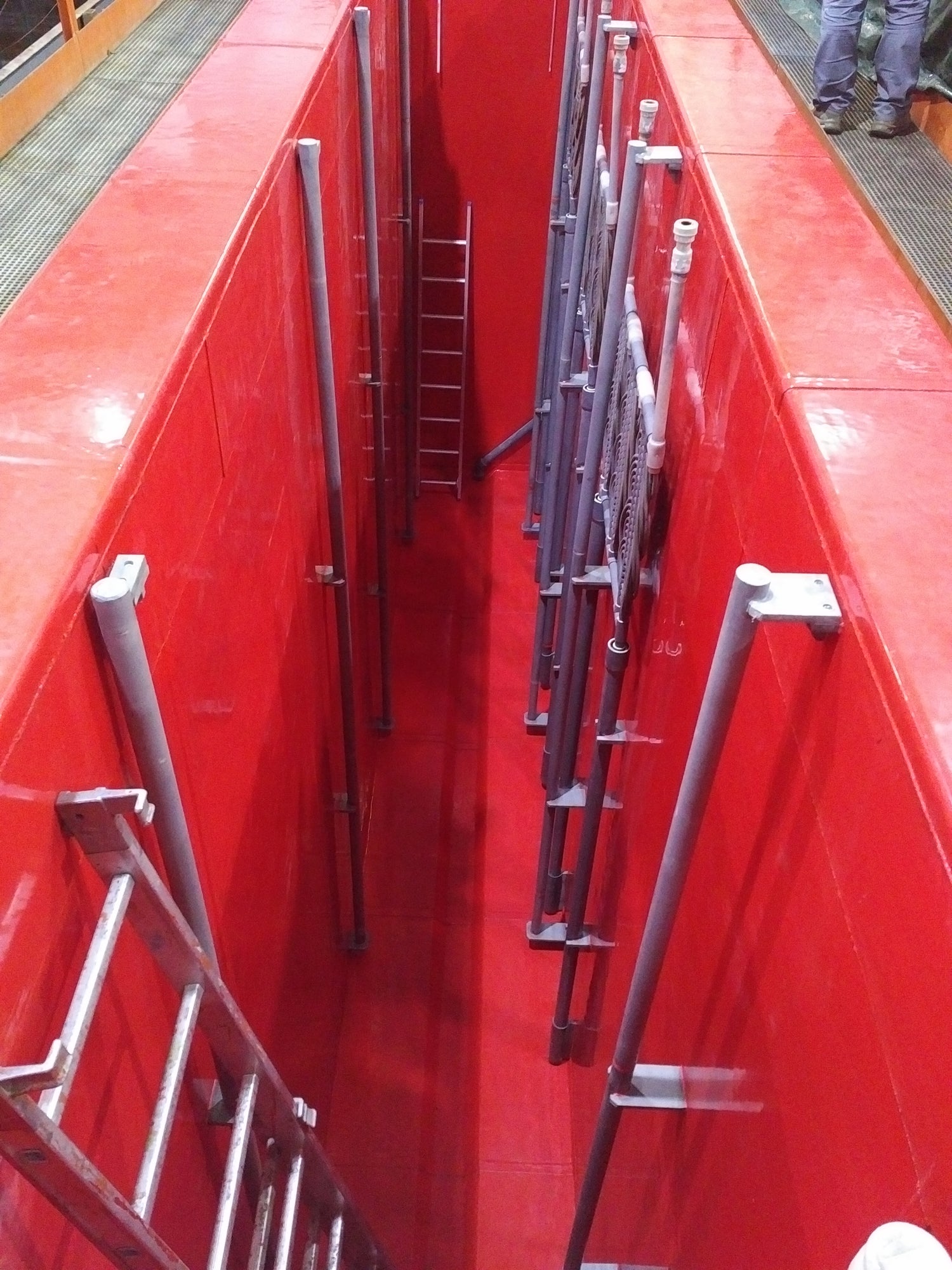

Step 3: Replacing the components

If your tank (like the one in the photo) had some hindering components in the coating phase, we will take care of completely reassembling them when the job is done.

And to replace them with new pieces supplied by us if necessary.

The tank illustrated above had pipes in ferrous material totally corroded by hydrochloric acid, consequently we rebuilt the PVC pipes when the coating was completed.

Coatings Proof of any chemical agent

Whether it is hydrochloric acid, cyanide or any other acid that is difficult to contain and whatever the material to be coated, we will have a solution.

Simply ask for a Free Estimate and we will evaluate together the best material to use and the timing of the intervention.

Some of our coatings

Request a Free Quote

We will respond as soon as possible to any request, for emergencies you can contact us by phone at: 011 974278 - We are open from Monday to Friday from 8:30 to 16:30 .